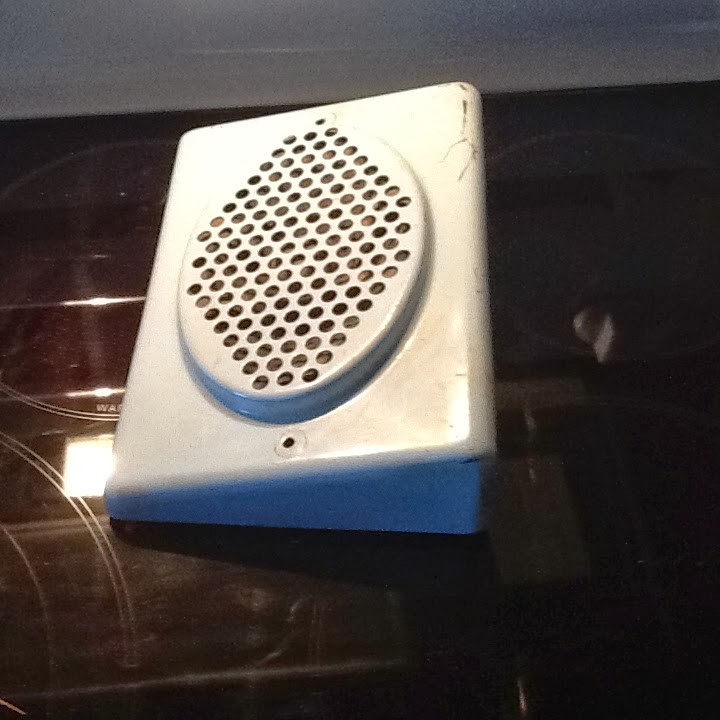

This blog is to document the fabrication of three speaker boxes for two Stude buddies. The original speaker box that was used in Transtar trucks looked like this:

This is a whacky speaker. It looks like the magnet is missing but it is on the other side of the cone. Looks like this design is specific to make the speaker as shallow as possible. A current, modern 4" x 6" speaker would not fit this box because the box is not deep enough. So, the answer to is come up with a new design that can accommodate current speaker design.

Here is the cutout plan for the new speaker boxes:

To make a box that at least could be viewed as period correct is to retain the grill design. The problem is that all new speaker designs, at least for cars, are surface mount. As a result, manufacturers can build speakers that have tweeter drivers that protrude from their frame. To work around this a spacer is needed to set the speaker back away from the frame.

This a typical 6-1/4" car speaker

Note the protruding tweeter

This a 6" PVC pipe adapter that is very close to the dimension needed. I plan to cut off a length (the amount that the tweeter protrudes) and remove a portion of the perimeter and re-glue the ends to make a spacer of the correct diameter.

6" standard PVC dimensions

PVC pipe as measured = 6-9/16"

Speaker rim inside dimension = 6-1/8"

Pipe to large to fit inside speaker rim

So, how much do I cut out?

PVC pipe as is = 6.525" * 3.14 = 20.4885"

To fit speaker = 6.125" * 3.14 = 19.2325

Therefore, 20.4885" - 19.2325" = 1.256"

My plan is to cut a 1-1/4" section out and using some wire to cinch down the perimeter so that the ends come together and then heating it up to reform to the new smaller diameter. After cooling glue the ends.